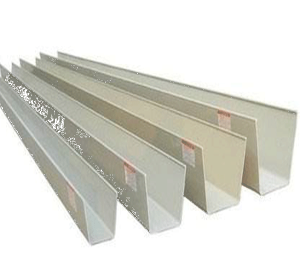

1. Color steel sandwich panels are often of the tongue and groove insertion type, which have the advantages of convenient installation, time-saving, material saving, good flatness, and high strength. They are particularly suitable for suspended ceilings and partition systems. 2. Thickness (mm): 50-2

1. Color steel sandwich panels are often of the tongue and groove insertion type, which have the advantages of convenient installation, time-saving, material saving, good flatness, and high strength. They are particularly suitable for suspended ceilings and partition systems.

2. Thickness (mm): 50-250;

3. Length (mm): Due to continuous molding production, the plate length can be determined according to user needs;

4. Width (mm): 1150 (1200) (960) (950)

5. Core material performance: A. Polystyrene bulk density: ≥ 15kg/m3 Thermal conductivity coefficient ≤ 0.036W/m.K Service temperature: about 100 oC

B. Volume density of rock wool: ≥ 120kg/m3 Thermal conductivity: ≤ 0.043W/m.K Service temperature: about 500 oC A | Non combustible: Class B1 B, Non combustible: Class A

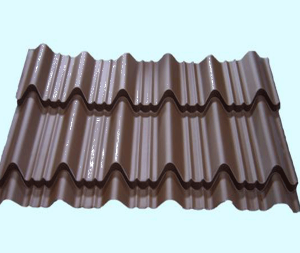

A. The 950 corrugated color steel sandwich panel integrates corrugated panels and sandwich panels, which increases the strength three times compared to ordinary flat color steel sandwich panels. It uses hidden self drilling screws to connect with the roof truss, without damaging the exposed parts of the color coated panel, extending the service life of the color steel sandwich panel; The connection between the plates adopts a buckle type, which is convenient for construction, improves efficiency, and is characterized by less water seepage.

B. The core material of the rock wool insulation color steel sandwich board is mainly made of basalt and other natural ores, which are melted into fibers at high temperature, added with an appropriate amount of binder, and solidified and processed. This product is suitable for insulation and sound insulation of industrial equipment, buildings, and ships, as well as for suspended ceilings and partitions in purification rooms, explosion-proof and fireproof workshops.

C. The bonding strength of PU polyurethane color steel sandwich panel sandwich panel shall not be less than 0.09MPa, and the combustion performance of the sandwich panel shall reach B1 level. When the deflection of the sandwich panel is Lo/200 (Lo is the distance between supports), the bending bearing capacity of the sandwich panel shall not be less than 0.5Kn/m2

Thermal insulation

The commonly used insulation materials for this color steel plate composite board include rock wool, glass fiber cotton, polystyrene (EPS), polyurethane, etc., with low thermal conductivity, which has good insulation effects for activity rooms, integrated houses, steel structure workshops, etc. High strength color steel plate adopts high-strength steel plate as the substrate (tensile strength 5600kg/cm), combined with advanced design and rolling forming. Therefore, the color steel plate activity room has excellent structural characteristics.

2. Thickness (mm): 50-250;

3. Length (mm): Due to continuous molding production, the plate length can be determined according to user needs;

4. Width (mm): 1150 (1200) (960) (950)

5. Core material performance: A. Polystyrene bulk density: ≥ 15kg/m3 Thermal conductivity coefficient ≤ 0.036W/m.K Service temperature: about 100 oC

B. Volume density of rock wool: ≥ 120kg/m3 Thermal conductivity: ≤ 0.043W/m.K Service temperature: about 500 oC A | Non combustible: Class B1 B, Non combustible: Class A

A. The 950 corrugated color steel sandwich panel integrates corrugated panels and sandwich panels, which increases the strength three times compared to ordinary flat color steel sandwich panels. It uses hidden self drilling screws to connect with the roof truss, without damaging the exposed parts of the color coated panel, extending the service life of the color steel sandwich panel; The connection between the plates adopts a buckle type, which is convenient for construction, improves efficiency, and is characterized by less water seepage.

B. The core material of the rock wool insulation color steel sandwich board is mainly made of basalt and other natural ores, which are melted into fibers at high temperature, added with an appropriate amount of binder, and solidified and processed. This product is suitable for insulation and sound insulation of industrial equipment, buildings, and ships, as well as for suspended ceilings and partitions in purification rooms, explosion-proof and fireproof workshops.

C. The bonding strength of PU polyurethane color steel sandwich panel sandwich panel shall not be less than 0.09MPa, and the combustion performance of the sandwich panel shall reach B1 level. When the deflection of the sandwich panel is Lo/200 (Lo is the distance between supports), the bending bearing capacity of the sandwich panel shall not be less than 0.5Kn/m2

Thermal insulation

The commonly used insulation materials for this color steel plate composite board include rock wool, glass fiber cotton, polystyrene (EPS), polyurethane, etc., with low thermal conductivity, which has good insulation effects for activity rooms, integrated houses, steel structure workshops, etc. High strength color steel plate adopts high-strength steel plate as the substrate (tensile strength 5600kg/cm), combined with advanced design and rolling forming. Therefore, the color steel plate activity room has excellent structural characteristics.