Guang'an color steel plateRelated installation methods

Steps/Methods

1. Setting out: According to the drawing and on-site measured dimensions, set out (partition centerline) and pop it into the ground rail at the intersection of the two edge centerline and the ground

Centerline. Ensure that these four lines are in a vertical plane to ensure the verticality of the wall surface for future installation.

2. Sky rail: The installation should be neat, and the interface should be reinforced and repaired. It should be fixed to the cement ceiling with nails or screws every 500mm-600mm.

3. Ground rail: When installing the ground rail, the installation position of the door should be reserved first, and attention should be paid to the issue of ground deviation. If there is too much height difference on the ground, it is necessary to level it

The drop is reduced without affecting the adjustment of the level. It is fixed on the floor every 600mm by hitting or screwing, and if the floor seam is too large, it is filled with sealant.

4. Edge trimming: Cut and trim the edges according to the actual measurement values, and trim the edges after cutting. Strive for neatness and consistency, with no gaps at the joints. Pay special attention to the interface with the sky track and skirting board, and ensure that there are no gaps.

5. Vertical keel: A vertical keel (half the size of the partition) is placed every 49cm, and the columns on both sides of the door frame are completely fixed, so as not to

When shaking, add a vertical keel in the opposite direction. If the width of the door leaf exceeds 90cm, the horizontal column on the door frame must be reinforced and fixed, and if necessary, welded to fix it.

6. Horizontal through center keel: If the height exceeds 3 meters, place one keel in a vertical direction of 1.2 meters. When connecting the two keels, they must overlap and overlap

The length shall not be less than 10cm.

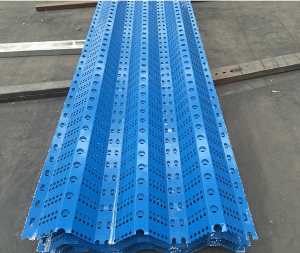

7. Wall panels: Install color steel plates from one side and install them in sequence, with a spacing of 12mm between connecting panels. 12mm wide pressure strips are used between the partitions,

Standard unit wall panels are interchangeable

matters needing attention

1. Pay special attention to the details when installing the wall panel. Firstly, use a pallet truck to transport the wall panel to the vicinity of the installation point. Use suction cups to upright the metal panel, with the lower end resting on the skirting board. The lining board should be close to the vertical keel on both sides, with a spacing of 12mm between one side and the other wall panel to fix the component on top. Use self tapping screws to fix it on the vertical keel with a spacing of 300mm to 400mm. Pay attention to the horizontal and vertical during assembly. When the next wall panel needs to be cut, It must be measured in size, cut and trimmed in the correct way, and installed on the wall.

2. The corners of the wall are trimmed and the internal corners are treated with a "U" shaped internal corner trimming strip.

3. In order to achieve an overall aesthetic and elegant effect, the corners and columns can be made of factory customized color steel plates.

4. The corners of the wall are professionally trimmed in the same color to maintain consistency with the wall. The charm of life comes from its diversity, and each person's different understandings also endow it with rich colors. Whether it's warm or peaceful, noisy or quiet, everything exists in that small box made of bricks and stones.