As we all know, rock wool sandwich panels are a type of sandwich panel that not only flame-retardant but also has insulation effects, and is resistant to high temperatures. They are a good choice for all paint rooms, ovens, soundproofing rooms, and so on. Therefore, there are several types of rock wool sandwich panels on the market:

1. Color steelRock wool board---Double sided color steel, with rock wool core material in the middle, can be used as partition walls orActivity board houseBoard. The regular widths are 950mm and 1150mm

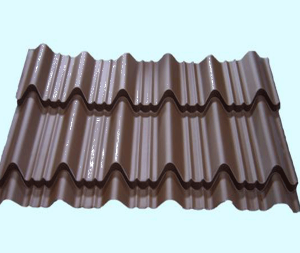

2. Color steel rock wool tile board - This is a type of color steel tile board with thermal insulation and insulation effects, with two sides of color steel and a rock wool core material in the middle. The difference is that its surface has wave peaks, commonly known as "corrugated", so color steel rock wool tile board is also known as "roof corrugated". The regular width is 840mm and 950mm

3. Color steel rock wool kiln board - This is a type of kiln board that is resistant to high temperatures and also has insulation effects. The density of this type of rock wool is relatively high, usually above 80K, making it a good choice for car paint baking rooms, drying machines, and baking rooms.

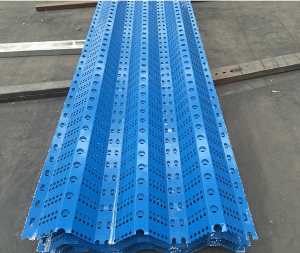

4. Color steel rock wool soundproofing board - This is a sandwich board with high production process requirements. One side of the color steel plate can be fully punched or semi punched, and the soundproofing effect is very good.

The above are rock wool sandwich panels with high customer demand. At the same time, when ordering boards, we need to pay attention to the following details:

Firstly, the control of appearance and quality is very important, so when we buy boards, we will choose materials with a flat and beautiful surface, no stains or damages, or require the manufacturer to produce according to our requirements.

Secondly, combustion performance is of utmost importance. Combustion performance refers to all physical and chemical changes that occur when building materials are burned or exposed to fire. This performance is measured by the characteristics of the material surface, such as ignitability and flame propagation, heat generation, smoke generation, carbonization, weight loss, and the generation of toxic products. So the manufacturer will be required to have relevant fire prevention and testing reports.

Finally, hygroscopicity is also a factor that cannot be ignored. Hygroscopicity refers to the property of a material that can absorb moisture in the air. Its moisture absorption ability is relatively strong, and in addition, it is also related to the diameter and structure of the pores. The hygroscopicity of rock wool products in the air is 3.9% moisture absorption per square meter, which can keep the room dry and prevent moisture.