In the rapid development of technology, especially the development of heavy industry. The characteristics of color steel plates are getting better and better. The sales personnel of Chengdu color steel plate will talk about the development trend of color steel plate.

Firstly, with the use of high-quality substrates, the requirements for the surface, shape, and dimensional accuracy of the substrates are becoming increasingly high. For outdoor use, zinc alloy hot-dip galvanized coils such as small zinc flake flat hot-dip galvanized steel coils and non zinc flake flat hot-dip galvanized steel coils are emerging in a timely manner; Indoor use such as galvanized steel coils, coated cold rolled sheets, and aluminum coils.

Secondly, improving the pre-treatment process and pre-treatment fluid, with a small number of equipment and low cost, has become the mainstream process, continuously improving the stability, corrosion resistance, and environmental performance of the pre-treatment fluid.

Thirdly, focus on the development of new coatings, improving general polyester, polyvinylidene fluoride (PVDF), and plastic sols to achieve super color reproducibility, UV resistance, sulfur dioxide resistance, and improved corrosion resistance; Develop functional coatings that are resistant to pollution and absorb heat.

Fourthly, the unit equipment is more complete. For example, adopting new welding machines, new roller coating machines, improving curing furnaces, and configuring advanced automation instruments.

Fifth, due to the lower cost of cold embossing compared to hot embossing, as well as its aesthetic, three-dimensional, and high strength characteristics, cold embossing production technology has become a development trend.

Sixth, pay attention to the diversification, functionalization, and high-end of products, such as deep drawing color coated boards, "pomelo peel" color coated boards, anti-static color coated boards, pollution resistant color coated boards, high heat absorption color coated boards, etc.

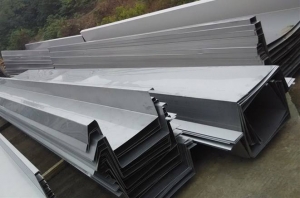

Color steel plate characteristics:

Color steel plate coating is a product made from cold-rolled steel plate, galvanized steel plate, Sichuan color steel plate, after surface chemical treatment, coated (roller coating) or composite organic film (PVC film, etc.), and then baked and cured. Some people also refer to this product as "pre roll coated color steel plate" or "plastic color steel plate". Color coated steel plate products are produced in rolls by manufacturers on continuous production lines, hence they are also known as color coated steel plate rolls. Colored steel plates not only have the properties of high mechanical strength and easy forming of steel materials, but also have good decorative and corrosion resistance of coating materials. Color steel plate is an emerging material highly regarded in the world today. With the progress of technology, the enhancement of environmental awareness, and the improvement of people's living standards, color steel movable houses are increasingly showing strong vitality and broad market prospects, and are favored by construction, home appliances, electromechanical, transportation, interior decoration, office appliances, and other industries.

Colored steel plate activity rooms have the advantages of lightweight, high-strength, thermal insulation, aesthetics, and durability, making them a high-end building that integrates architecture and decoration for quick installation. The construction and cleaning of color steel movable houses are widely used in large-span factories, warehouses, office buildings, villas, rooftop floors, air purification rooms, cold storage, shops, sales booths, and temporary buildings. Light colored steel plate sandwich panels with a weight of less than 14KG per square meter can fully reduce structural load and reduce the structural cost of activity rooms.

Convenient installation

The light weight, spliced installation, and the ability to cut freely of the color steel plate activity room determine its ease of installation, greatly improving efficiency, and saving time. The surface material and insulation material of the fireproof color steel plate sandwich panel are non combustible materials, which can fully meet the fire protection requirements of the activity room.

durable

Various studies have shown that after more than 40 years of widespread use abroad, it has been confirmed that color steel plates treated with special coatings have a shelf life of 10-15 years. Afterwards, anti-corrosion coatings are sprayed every 10 years, and the lifespan of activity room panels can reach over 35 years

The beautiful pressed color steel plate has clear lines in dozens of colors, which can meet the needs of any style of activity room building and achieve satisfactory results.

Thermal insulation